Any events occurring in the world impact business: elections, wars, crises, and bankruptcy. Only companies that invest in their development and modernization have a chance to survive. Today it is crucial not only to reduce your costs but also to increase your income. The introduction of the latest technologies can help a lot. This article will discover what IoT technologies (Internet of Things) and the Industrial Internet of Things are and how they help solve business problems.

The world of technology is developing rapidly, and devices such as refrigerators and cars have learned to connect to the network and exchange data without human intervention. Hardware, software, communication infrastructure, as well as “connected” devices participating in the data exchange process are combined into a technological ecosystem called the “Internet of Things” (IoT). The widespread adoption of the Internet of Things is driven by the proliferation of devices equipped with electronic components, software, and communication capabilities, whether it be a smartphone, a camera on an oil rig, or an optical sensor on a steel mill, that collect and transmit data.

The pace of adoption of connected devices and new data streams in manufacturing is impressive. We expect the rate of adoption to accelerate further, significantly, as the cost of infrastructure (e.g., sensors, computing power, data storage) decreases and the analysis of data received from devices and processed by cloud IoT platforms becomes easier. In turn, platform-based applications contribute to the emergence of entirely new analytics types obtained in real-time or as close to it as possible. According to some estimates, the Internet of Things could bring about $4 trillion to manufacturers in the next decade through increased revenues and reduced costs.

Industrial Internet of Things and how it works

So, initially, sensors, actuators, controllers, and human-machine interfaces are installed on critical parts of the equipment. Information is collected, which subsequently allows the company to acquire objective and accurate data about the enterprise’s state. The processed data is delivered to all enterprise departments, which helps establish interaction between different departments’ employees and make informed decisions. Besides, it helps to accumulate the expertise of specialists.

The obtained information can be used to prevent unplanned downtime, equipment breakdowns, reduce unplanned maintenance, and supply chain management disruptions, thereby allowing the enterprise to function more efficiently.

When processing a vast array of unstructured data, their filtering and core interpretation prioritize enterprises. In this case, the correct presentation of information in a form understandable to the user is of particular importance; analytical platforms designed to collect, store, and analyze data on technological processes and events in real-time usually help in this.

Avoiding downtime and maintaining security in the enterprise requires the introduction of technologies that detect and predict risks. Continuous monitoring of critical indicators makes it possible to identify the problem and take the necessary measures to solve it. For operators’ convenience, modern systems allow visualizing the conditions of technological processes and identifying factors that influence them using any web browser. The online analysis helps users find the root cause of problems faster.

These solutions turn production data into useful information necessary for the safe and efficient management of the enterprise. The introduction of such technologies enables enterprises from different sectors of the economy to obtain certain advantages.

Let’s take an example. By adopting technologies for collecting, storing, and analyzing data (for example, sensors, controllers, analytics software, telemetry, big data, and cloud computing), manufacturers can predict the need for equipment maintenance before a problem occurs, thus preventing disruptions in production processes. You can control the appearance and quality of individual parts using optical sensors or cameras. After that, a barcode or RFID (Radio Frequency Identification, radio frequency identification) tag is attached to the part, which allows you to electronically trace the entire supply chain of this part, including even its use by the customer. In this way, connections are formed between machines and between machines and persons. Manufacturers are starting to use IoT and data analytics technologies in their operations to stay competitive. Today we will talk about building a system for monitoring IoT, but first, we will define this concept.

The Internet of Things is based on the technology of machine-to-machine communication (M2M). It is when machines use mobile networks to exchange information with each other or transmit them unilaterally. M2M technology is used in health and safety systems, manufacturing, housing, communal services, energy, and banking systems.

IoT brings these things together into a single system

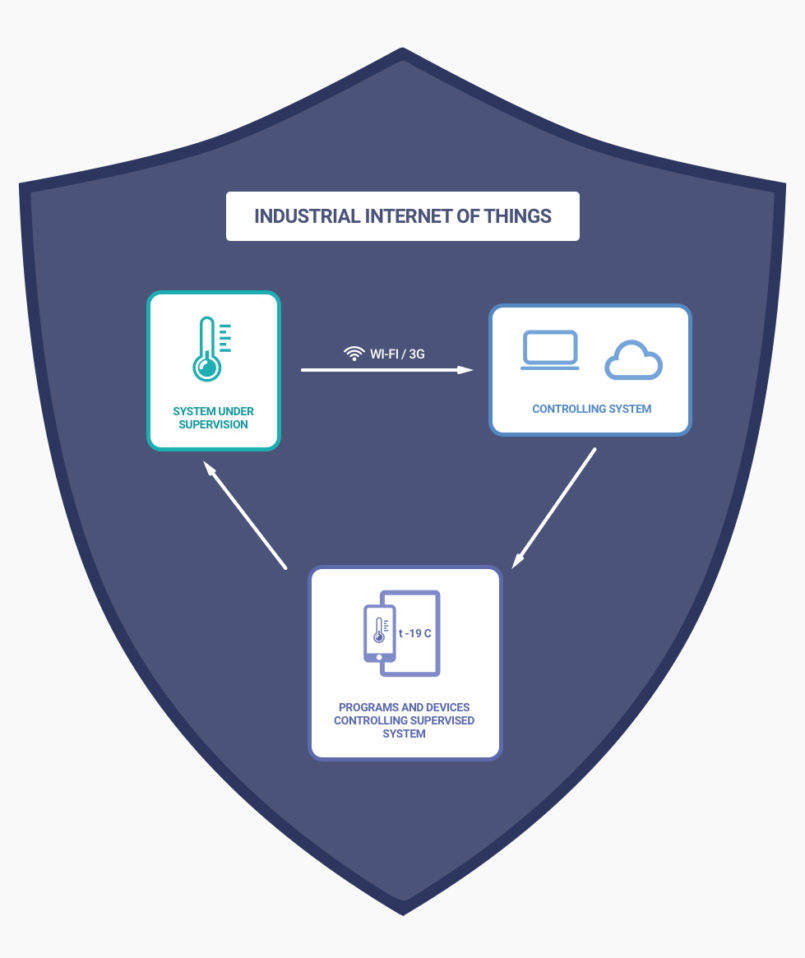

The industrial Internet of Things system is similarly structured. This system includes:

- Sensors and readers. They collect, verify, analyze, and send information.

- Mobile communications, Wi-Fi.

- Special platforms that control applications, devices and analyze data.

- Software and mobile applications. They process information, create predictive models, and control devices.

- Security control. A critical component that is responsible for the safety of all processes.

So far, IoT technologies are not being implemented as quickly as we would like. But it is already clear that the future belongs to such technologies. And for some cities, this future has already arrived.

IoT technologies are not only convenient. However, the ability to delegate all routine matters and processes to the system is worth a lot. First of all, it is security and control. Wherever you are, you are in complete control of your business. On a city scale, the benefits are even more apparent: technology can optimize urban transport or utility costs. For example, smart trash cans will only send a signal to garbage trucks when they are full. The system will analyze the data and make the best route for garbage trucks. And instead of driving on schedule, cars will only come when needed.

Already, the industrial Internet affects almost all spheres of life and business:

- Production area. Factories, factories, and private workshops.

- Public administration. It includes solutions to help the government operate more efficiently and to ensure the safety of residents.

- Home and city solutions.

- Cross-industry. IoT solutions that are used in all areas.

What is IoT Monitoring? And Why is it important?

Internet of Things (IoT) monitoring is the process of discovering, assessing, monitoring, and managing connected devices. IoT monitoring informs you of any issues with your IoT assets that impact business and production-critical applications and service performance.

It is worth saying that the IoT, which is used in production, is commonly called the Industrial Internet of Things. With IIoT, industrial companies can digitize processes, modify business models, and improve productivity and efficiency while reducing costs.

Each device you add to your network uses resources, generates data, and interacts with other devices and services. It means that by adding new devices, you put yourself at risk and impact the performance of your applications, systems, and services. Therefore, it is essential to have in your arsenal such tools for monitoring and managing IoT devices to collect data with the highest quality, process, and display the necessary reports, and ensure data security.

Today, many industrial enterprises implement IIoT in their operations to increase productivity by identifying and preventing potential bottlenecks, disruptions, quality problems, and more. Thus, we have come to the next point and now let’s talk about the benefits of IoT Monitoring.

Benefits of IoT Monitoring

With IoT monitoring, you can analyze your systems and handle billions of events and alerts. It also allows you to bridge the gap between devices and business processes to gain the information you need to solve critical problems and improve productivity.

Implementing an IoT monitoring solution is an innovative method that you can use to track your equipment’s performance in real-time. By using IoT performance monitoring tools, companies can achieve tangible results, such as:

- Get real-time data and a deep understanding of all components of the IoT ecosystem. You will be able to improve the quality of customer service, fix problems, and so on.

- Understand the data transfer rate, where the delays occur, and where these bottlenecks are.

- Collection and analysis. Analyze a wide variety of IoT data across the Internet across connected devices, clients, and apps.

- Bridg performance gaps. Optimize the performance of a variety of applications, APIs, networks, and protocols.

- Real-time alert system. Get alerted to problems before significant business impact occurs.

- Improved resource utilization and extended the service life of the equipment. Limited visibility of equipment degradation can lead to costly replacement, so the sensors must report equipment problems.

Without early warning of potential degradation, organizations cannot:

- Sustain reliability. To minimize downtime and reduce overhead costs

- Enhanced machine efficiency by understanding the performance and health of it

- Increased ROI

- Supply chain optimization

- New values for the consumer. A company that uses new technologies offers a brand new product. For example, uncrewed tractors for agriculture are equipped with sensor sensors that monitor the soil’s state, show them what fertilizers are needed and what quantity.

- Boosted Overall Equipment Effectiveness (OEE is a powerful tool that helps you diagnose and manage production units across various industries.)

Leveraging IoT Monitoring and Performance bring real-time benefits to many industries. Instead of spending hours or even days identifying a problem’s submission, a monitoring tool can quickly and efficiently locate the problem’s source, correlate data, and enable a company to recover the process soon. It improves reliability, increases customer satisfaction and retention, and reduces overall product support and ongoing maintenance costs. Let’s look at how the industrial Internet of Things is organized and what types of IoT solutions for monitoring are their advantages and disadvantages.

IoT monitoring solutions

By receiving data from a smart sensor installed at different stages of production, for example, a company can monitor the status of facilities and the environment in which products are manufactured. All this happens in real-time. All monitoring results can be collected, processed, and applied for analysis and further optimization in the future.

The data obtained from monitoring makes it possible to evaluate the performance of equipment from different points of view, identify new patterns and trends, and much more. Monitoring is an essential process in preventive maintenance as users of the IoT system can identify problems before damage occurs and take the necessary action.

Data storage and display to users

IoT devices can provide comprehensive information about the environmental conditions or the health status of patients to medical workers, equipment in factories and factories, and more.

By monitoring objects, processes, and events, you can better understand the operational value. For example, Deutsche Bahn uses IoT monitoring to generate new data and improve rolling stock’s operational efficiency.

Thanks to the IoT, the railway company can track the loading of wagons and their location, the position of the rolling stock at the moment, which improves the experience of the company and its customers. Trains can be equipped with sensors to monitor the condition of parts of the train: brakes, wheels, and engines.

In particular, IoT monitoring helps optimize any public transport operation by measuring passenger traffic to identify at which hours and days additional transport is required on the route and when it is possible to increase public transportation intervals.

In-depth analysis and identification of specific situations

An IoT system can receive and display sensor data (such as temperature or humidity) and draw inferences about what specific values might mean. For example, an IoT system can detect anomalies and predict disruptions and find their root causes. It happens by comparing the current data and those previously received (stored in the cloud), and if there are discrepancies, the system will notify that a failure is about to happen. This way, the company can fix the problem before it happens.

It is worth noting that IoT can be used not only for monitoring but also for remote control of connected devices and carrying out certain operations with their help.

Manual IoT Monitoring Solutions

An IoT system can solve specific problems even without human intervention, but sometimes human intervention is required. For example, when some part of the machine fails, then intervention is necessary. In other words, manual control is required when the IoT system encounters unfamiliar input data, and a person is needed to work with them correctly. In the future, data on user actions in response to specific sensor data can be used by the machine learning module to create models for control applications and contribute to further automation of the system.

IoT Automated Monitoring Solutions

The automated system of the Internet of Things performs all operations using commands to the actuators. The system decides on a specific command based on the data that comes from the sensors. There are the following types of automated control solutions:

Rule-based management

This type of decision implies that algorithms will perform all actions upon receipt of specific data from sensors. Rules are formulated before the system is put in place. For example, Deutsche Bahn uses IoT monitoring and other railway companies to use such solutions to measure temperature, vibration, and other cargo parameters. All data is sent to the cloud, and the monitoring system compares the previously saved parameters. Only those received, if there are differences from the permissible values, the control applications send commands to configure these parameters.

Machine Learning Control

The most advanced form of IoT systems is machine learning-driven systems. With its help, data from sensors are collected continuously and used in machine learning algorithms. New models are created and then validated by analysts and/or data scientists for correctness. After confirming the correctness of the models by specialists, they can be used in the IoT system.

The basis for machine learning can often be the analysis of human commands – people’s reactions to specific sensor data are accumulated in a big data warehouse. Then models are built of how to act in a given situation, given people’s recorded actions under similar circumstances.

Of course, machine learning can also occur based on camera shots, when pictures of potential problems are handled, sent for analysis (either manual or computer). In the cloud, data is accumulated, and systems are trained to identify issues without human intervention and send appropriate notifications.

The potential for machine learning is enormous, and, as a result, is ideal for optimizing all sorts of processes. Since studying the system, compiling statistical data, an intelligent system can identify the most optimal ways to use resources (time, materials, working hours, and so on).

How the Industrial Internet of Things Will Change Business

IoT in agriculture

Today, many companies in the agricultural sector still rely on expert opinion in terms of soil treatment (fertilization occurs on schedule, not on demand). IoT is fundamentally changing the way we work, as all mechanisms are equipped with sensors. When the tractor plows the land, the sensor analyzes the soil’s condition in a specific area. The system itself calculates the required amount and type of fertilizers and applies them to the ground.

When crops emerge, sensors monitor moisture levels, nutrients, and pests. For example, if the dry land – the sensors analyze the moisture level and, if necessary, turn on irrigation, moreover in a specific place, and not throughout the field. This approach increases yields and saves resources. For more information on how IoT can be used in agriculture, please read our article IoT and Automation Technologies in Agriculture.

IoT in industry

The introduction of IoT in factories and plants will reduce the number of personnel, maximize the use of resources, and increase income several times. For example, with their help in the plant, you can correctly distribute orders and load existing equipment to 100%, avoiding downtime.

Industrial IoT solutions have enormous potential. The introduction of this technology allows you to save on equipment maintenance and repairs. The master does not always notice minor breakdowns due to which the mechanism may fail for a long time. As a result, downtime and expensive repairs. The use of special sensors will provide up-to-date data on the condition of the equipment and prevent breakdowns. It also includes accounting for warehouse balances.

IoT in energy

Meters that themselves transmit readings and show each electrical appliance’s consumption are beneficial for both the service provider and the consumer. All this makes it possible to use energy resources economically.

IoT in healthcare

In medicine, the Internet of Things will allow you to move to a new diagnosis and treatment level. Special sensors and “smart” devices will monitor the condition of patients in real-time. If necessary, for example, when blood sugar rises, such a system can immediately administer the drug. New technologies will prevent heart attacks and strokes, blood clots, and more. For more details, see our article Deep Learning in Medical Diagnosis.

Invest in IoT monitoring tools

The first thing to say is that there are not so many IoT monitoring and management tools, and they are not as high-quality as network monitoring systems. Therefore, many companies that use IoT devices have to use free monitoring tools distributed by device manufacturers. Such tools are usually tricky to customize to fit your needs. They are also poorly or not compatible with business tools that are often already used by companies.

All of this is because IoT device manufacturers are not very interested in developing monitoring software. These tools are for them as a marketing incentive and not as a source of income. Therefore, as a rule, they are poorly designed with low-quality interfaces. All of these factors make it difficult to take full advantage of the IoT opportunity.

Of course, if buying a device with an accompanying monitoring tool, you may not immediately want to invest in developing a custom monitoring tool. But on the other hand, an ordinary monitoring tool will not give you the promised result 100%, since it will not meet all the needs of your business.

IoT devices are considered to save time and money in the modern world, but what if they don’t do their job, or are they doing the right thing everywhere? In this case, they jeopardize the speed of your business. A custom IoT device monitoring tool can ensure that your IoT infrastructure is running efficiently and consistently. Therefore, such an investment will pay off rather quickly and allow your business to reach a whole new level.

To sum up

Opportunities for continuous production control through an IoT solution allow you to clearly understand the volume of production and quality and predict them for a particular time horizon.

You can correlate this information with general economic trends, market dynamics, and, using a mathematical model based on historical data, set a favorable market price for your products, ensuring maximum profit. Optimizing the current production cycle will make it possible to seriously improve production processes, which will positively affect the enterprise’s work.

FAQ

- able to cope with the rapid growth of traffic and data volumes; can work simultaneously with IPv4 and IPv6 protocols;

- the ability to manage all new devices, regardless of the communication standard or performance metrics;

- visibility of traffic in each segment with an accuracy of seconds;

- One-screen management of a hybrid cloud environment covers all monitoring levels, including physical, virtual KPIs.