When one of the biggest budget items of your company is physical assets, it is essential to efficiently manage their lifecycle and ensure that their potential is fully used.

Here, enterprise asset management (EAM) comes in handy and enables a structured approach to asset usage, procurement, and maintenance. Enterprise asset management software enhances the value of this practice and digitalises the process of asset tracking.

The market offers different options for those who want to acquire EAM software. The main question concerns the form you should choose to implement this software piece. Should it be a separate application, or should it be a part of your ERP system?

In this article, we will talk in detail about different enterprise asset management software and analyse which option can generate the most value for your business.

What is Enterprise Asset Management?

Enterprise Asset Management (EAM) is a set of practices to ensure the reliability of assets and optimise their operational performance. This process relies heavily on asset lifecycle management, which helps gain better control over asset health.

EAM plays a great role for enterprises that own a large number of complex and expensive physical assets, such as vehicles, heavy equipment, buildings, etc. It is especially relevant for such industries as manufacturing, construction, energy, space, defence, and others. Lack of asset management for these sectors leads to high expenses on asset support and maintenance processes, as well as adds a certain degree of chaos to the operations.

Centralised data management in ERP systems

Rather than juggling multiple sources of information, ERP consolidates asset data into one centralised place. This simplifies decision-making, reduces the risk of errors, and gives departments access to the same up-to-date information. It also helps break down the silos that often come with stand-alone tools, making collaboration smoother across the board.

Enhancing maintenance productivity with cloud ERP

Cloud-based ERP helps maintenance teams plan faster and more accurately. Real-time asset data gives planners, supervisors, and engineers the information they need to make timely decisions. With less guesswork and better coordination, teams spend more time doing the work that matters.

Integration of ERP with various business functions

ERP systems do more than manage assets—they bring together Finance, HR, Payroll, and Procurement on a single platform. This integrated approach helps teams work with the same data, reducing duplication and making cross-functional collaboration easier. For organisations looking to connect operations under one system, ERP provides the structure to do just that.

Comprehensive financial management in ERP

ERP offers full visibility into asset-related expenses, from purchase to retirement. By linking financial data directly to asset records, it’s easier to track valuations, forecast costs, and justify future investments. With everything in one system, finance teams can keep a closer eye on how assets impact the bottom line.

Eliminating manual processes with ERP

Manual maintenance logs and duplicated data don’t just waste time—they lead to mistakes. ERP systems automate many of these tasks, allowing for more consistent, accurate workflows. Categorising maintenance activities and standardising them through the ERP module also helps teams plan better and execute faster.

ERP systems and asset performance management

ERP tools don’t just track assets—they monitor how well those assets are performing. By analysing real-time data, ERP supports smarter maintenance planning and helps identify issues before they escalate. Over time, this improves reliability and supports long-term asset performance goals.

Real-time inventory tracking in ERP systems

Knowing where inventory is, how much you have, and what it’s worth shouldn’t be a guessing game. ERP systems track this information in real time, offering visibility into location, value, and quantity. That kind of clarity helps reduce shortages, overstocking, and wasted spend.

Predictive maintenance capabilities in ERP

Waiting for equipment to break down is costly. ERP systems support predictive maintenance by analysing patterns in asset performance data to help spot potential failures early. This leads to fewer unplanned outages and more reliable operations.

Cloud ERP applications for asset management

Modern cloud ERP platforms come with built-in best practices for maintenance, making it easier to standardise processes across the organisation. These systems also improve how assets are used by supporting better planning and reducing downtime, helping maintain business continuity in the long run.

Benefits of combining ERP and EAM for transit agencies

When ERP and EAM are used together, transit agencies gain better visibility into their assets and operations. The combined system supports more consistent reporting and makes it easier to manage everything from maintenance to budgeting. It’s a practical way to increase efficiency without adding complexity.

See also: Digital Transformation Stories in HR Industry

Asset Lifecycle Management

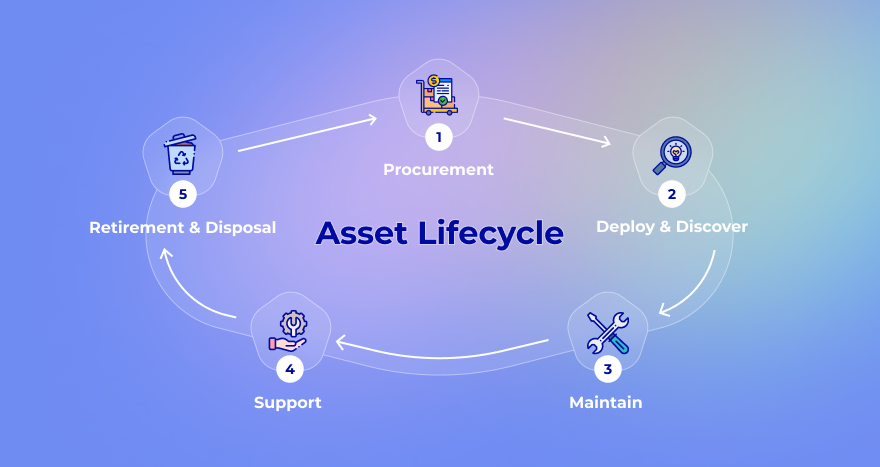

As we have already mentioned, the asset lifecycle is a basis used by enterprises to structure their asset management. It consists of several stages.

Planning

The first and most important stage is when you design the concept of your asset utilisation. Analyse what assets you lack, what requirements they should have, and how they should supplement and synchronise with the assets you already use.

Don’t rush through this step, as here you should build a clear vision of a new project. It is a great time to research new technologies (for example, digital twins, which gained popularity in the last few years) and run a digital transformation of your business, assess your needs, analyse current performance and optimise business processes.

At the same time, don’t forget about essential organisational aspects, like budgeting.

Acquiring

When you have created a plan, your next steps include purchasing and delivering the aforementioned assets to the facility where they will be used.

At this stage, you will take care of the set of activities: contract management, quality inspection, storage of the asset, spare part management, and others.

Deployment

This stage implies the assembling, installation and preliminary checks of the assets acquired and delivered. To succeed here, you should take care and think through the aspects like asset tracking and ownership, documentation, qualifications, future maintenance, and support strategies.

Operation

It’s the longest stage when the assets generate a return on investments, and for you, a person interested in multiplying the revenues, enterprise asset management is crucial.

During this phase, EAM software will schedule planned work activities, as well as track unplanned work. Another important role of the EAM system is to monitor asset health to gather a sufficient amount of data for you to plan and schedule maintenance activities and prevent untimely failures.

Maintenance

You can’t avoid asset maintenance, but you can manage it and implement maintenance strategies that would optimise it, and decrease downtime and disruption in the manufacturing cycle.

Asset maintenance can be divided into two types: planned and unplanned.

Planned maintenance is typically scheduled ahead and is preventive in its nature. Unplanned is more disruptive, as it’s required when the equipment breaks down or performs poorly. It may cause unplanned downtime that will affect the productivity of the enterprise and impact profits.

Hence, it makes sense to focus on planned maintenance or even implement cutting-edge technologies like the Industrial Internet of Things (IIoT) or artificial intelligence (AI) to enable predictive maintenance and amplify the monitoring process with real-time data on asset state.

Disposal

Every asset’s life comes to an end, and it is also a task for a company to leverage this experience instead of simply writing it off.

The main reasons why the asset might be disposed of are:

The life of the asset has come to an end, and it can’t be used anymore;

The asset isn’t fit anymore for your company’s needs and requirements;

Supporting the asset is too expensive;

The asset can be replaced with more modern technologies.

To get the most here, the company should take two actions: analyse the data about asset life (and EAM software is your helper here) and evaluate what value you can get from asset removal.

How digitalization can boost laundry business

EAM as a practice vs. EAM software

Enterprise asset management (EAM) stands for a set of practices designed to manage assets and maximise their efficiency and lifetime, reducing expenses on their support and improving their quality.

In turn, EAM software is a tool that helps you perform asset management and guides you through the lifecycle of every asset.

50 shades of Patient Engagement Software

Benefits of Enterprise Asset Management Software

An enterprise asset management solution is a software piece that will simplify your life and the life of your company. Let’s contemplate why and what results you can expect from EAM software implementation.

Real-time Asset Monitoring

EAM software enables real-time asset tracking, so companies can allocate their physical assets and gain full control over equipment wherever it is based. It is especially relevant for asset-intensive enterprises when it is hard to manually follow every asset and evaluate its state.

Real-time data allows for the adoption of more efficient strategies for asset usage, scheduling, and planned maintenance. It also reduces asset shortage or excess, as well as helps you to detect asset theft, loss, or misplacement almost immediately.

Enhanced Operational Efficiency

Delays and inflated costs on asset support are the main reason for headaches for maintenance and facility managers. Outdated workflows and process management based on spreadsheets and paperwork create an environment for disruptions and missteps.

EAM software digitalises your processes and hence, relieves your employees from repetitive and time-consuming data entry and gives them the opportunity to show their best. EAM software easily removes bottlenecks that can create challenges for efficient operations.

Improved Asset Reliability and Uptime

High uptime is a goal for every enterprise, as it maximises the production and profits you might generate with the help of acquired assets.

Adequately planned maintenance management, preventive in its nature, will help to prolong the life of your physical assets and reduce the number of sudden and inconvenient breakdowns that will block the manufacturing cycle.

Data Centralization

Like many other examples of business solutions, enterprise asset management software allows for the generation and storage of operational data within one space. It enables shared access between your employees and different departments, which, in turn, enhances collaboration and communication inside your company.

Access to In-depth Analytics

Wise business decisions come when quality analytics is available. EAM solutions help you to track the cost and their stream, from the moment the enterprise assets are bought to the total price of their maintenance over the whole asset lifecycle.

This data will grant you an understanding of the total cost of ownership (TCO). It will help you optimise your investments and expenses and leverage the in-depth reports for future growth.

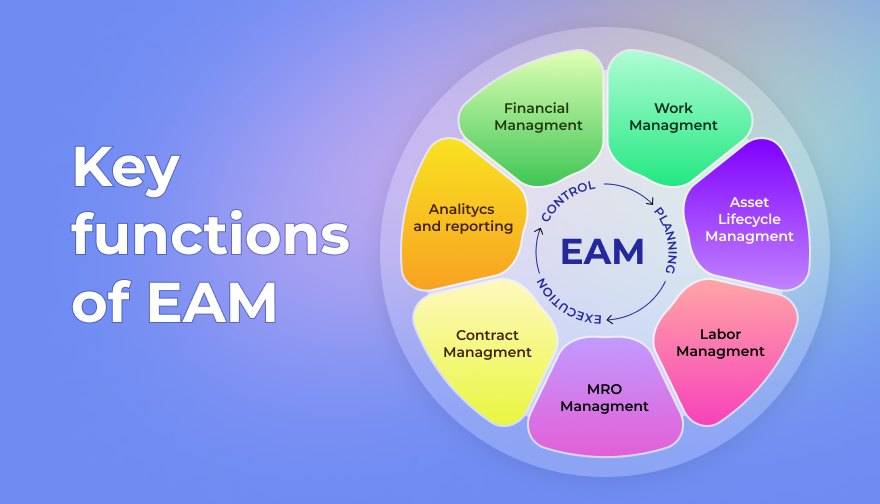

Main Features of Enterprise Asset Management Software

What features should your EAM software have? We gathered the main functionality you should pay attention to.

Lifecycle Management

We have already talked about the asset lifecycle being the basis of the whole enterprise asset management. Your EAM software should reflect all its stages and processes, including planning, procurement, installation, operation, maintenance, transfers, disposal, storage, etc.

A great enterprise asset management platform will allow you to properly track enterprise assets, their documents, and costs.

Work Order Management

Work order manages the asset maintenance requests inside your enterprise. Instead of assigning tasks manually and tracking them with spreadsheets, you can leverage an EAM system to simplify the process of task creation and completion.

This feature will also help you navigate easily through the dozens of tasks and employees and ensure that every process is streamlined, and every order is assigned to certain specialists and not lost among a variety of other requests.

Maintenance, Repair, and Operation (MRO) Inventory Management

MRO Inventory usually takes a big part of the budget, and hence, its improper usage may cost a lot. Inventory management within EAM software will help to track resources and parts procured for asset maintenance.

Through inventory transparency and constant tracking, you will be able to reduce losses, prevent theft, and hence, eliminate excessive expenses on this part of asset management.

Labor Management

Your employees responsible for asset management processes have even bigger value than any equipment or inventory you can acquire. Hence, we would say that labour management is one of the must-have features of your enterprise asset management software.

This feature will not only contribute to managing employees’ working hours and workloads, but also keep track of their certifications and keep a schedule of necessary training.

Financial Management

We talked about the efficiency of EAM software for financial analytics and transparency. Usually, it is implemented through a financial management feature, which is designed to analyse and calculate all essential financial data like the cost of production, the cost of downtime, emergency scenarios, etc.

Reporting

Adequate and detailed reporting and analytics enable adequate decision-making, based on data and predictions, instead of assumptions. Dashboards, charts, and other visualisation tools will show you your progress and state of equipment in detail.

Why EAM Solution Should Be Part of Your ERP System?

Enterprise asset management software is a must for plants, manufacturing, supply chain companies, etc. We have already mentioned that this type of solution helps to optimise asset management and control operational assets, enable preventative maintenance, and overall improve asset performance.

However, the question arises: should enterprises choose a specialised enterprise asset management software piece or integrate an EAM solution into their ERP application as a module?

We suggest the second option to you. ERP integration with an enterprise asset management solution allows better collaboration and data streamlining than these two software pieces would provide separately.

Here are the main benefits that integrating EAM with ERP will bring you:

no data duplicates and data centralisation not only within the asset management department but also with other units;

streamlined processes, enhanced collaboration within the whole enterprise, which leads to less miscommunication and tasks being stuck or delayed;

deeper insight into financials, as an EAM solution, will give you a better understanding of asset costs, and ERP will handle financial costs, depreciation, and capitalisation as a whole within your company;

easier and cheaper IT support, as the efforts of your IT crew will be directed to the one system instead of being scattered over several;

easier adoption for the team, as your employees would need to master only one system; it will make the implementation easier psychologically and reduce the time your team will lose while switching between interfaces.

Hence, integrated ERP and EAM software is a key to maximising the value enterprise asset management can bring to your company.

ERP Development with Altamira

Altamira is an experienced software development vendor. We specialise in custom ERP development and deliver business software designed for your needs, requirements, and goals.

Choose us to develop and implement your enterprise asset management software and benefit from:

a custom-designed solution that will enhance your processes instead of disrupting them;

a fully-staffed development team interested in delivering quality, self-sufficient products that will generate value for your company for years;

established development process built on 10 years of experience in software development;

a high level of ownership over the project and product quality;

highly qualified client success and delivery teams;

transparent and regular reporting on project progress and budget spent;

a strategic approach instead of reactive decisions.

Our ERP development services will cover everything you need to acquire and adopt a custom ERP system with an enterprise asset management module. We provide:

discovery stage and preliminary research to power the whole development;

full cycle of development based on Scrum methodology;

data migration to help your adoption of the system;

a long-term development strategy to deliver the most value with minimal possible delays and expenses.

Our Experience

We have created several ERP systems that generate revenue and optimise processes for our clients. Here are the most interesting cases we would like to share with you.

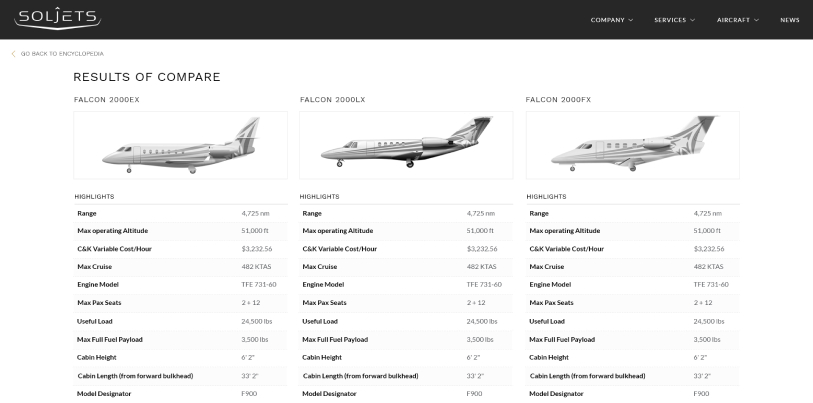

Soljets: Enterprise Resource Planning System for Jet Brokerage Company

Soljets is a jet brokerage enterprise that searched for the most optimal ERP solution to enhance its productivity.

We successfully managed to deliver such a software piece, and within 18 months, the client’s team has noticed significant improvements, including 2-fold growth in revenue.

Learn more about the Soljets case in our latest interview with our partner.

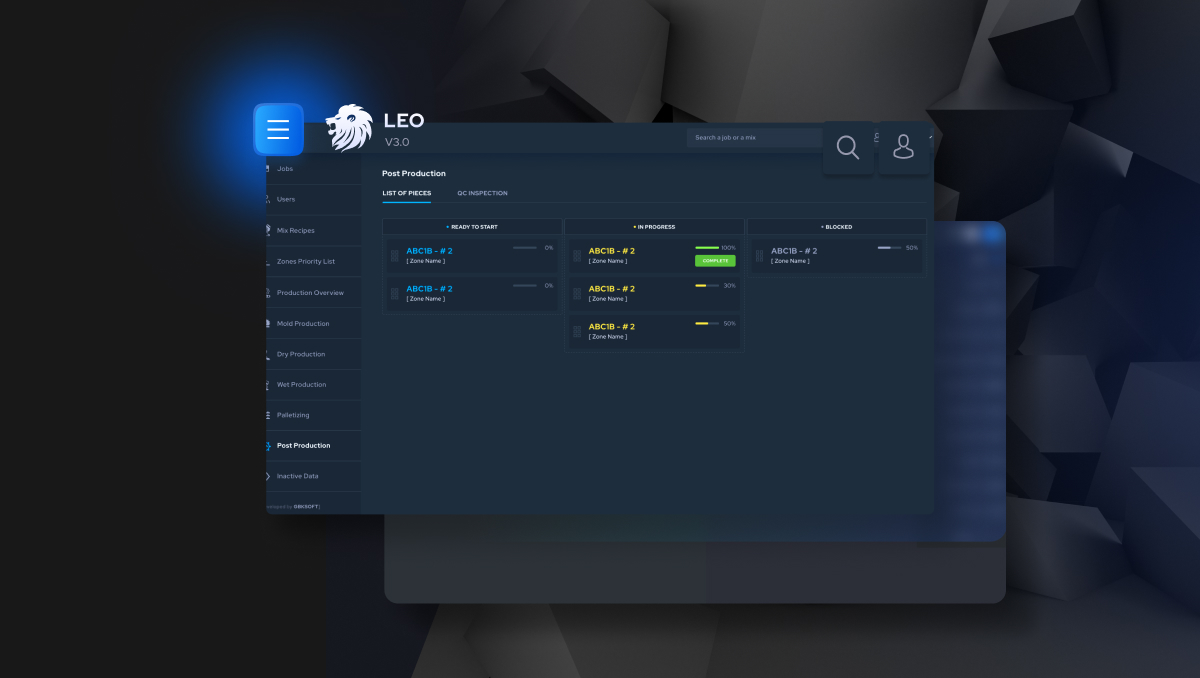

Leo: ERP System For a Construction Company

Leo is the name of the ERP system designed for the construction company. The application was delivered within 6 months and covered the main aspects of the client’s production cycle, as well as enabled data management automation.

Learn more about Leo ERP Functionality in this case description.

In Conclusion

Enterprise asset management software is one of the tools for asset-intensive enterprises that will make the biggest change in operational approaches. Asset tracking, maintenance management, and supply chain management become more and more efficient while being automated through EAM systems.

Integrating an enterprise asset management module in your ERP software will be the wisest move if you really want to get the most from this type of solution.

FAQ

EAM software is a system designed to manage all assets the company owns and track every stage of its lifecycle. As a result, it helps to optimise the cost invested in every asset and increase the profits it generates.

There are dozens of ready-made solutions on the market. They differ in price and functionality, and theoretically, you can always find a solution that will satisfy your needs. However, the biggest value will be a custom-developed EAM system.

Asset management functionality may be implemented through a separate solution that the company may acquire. It can also be represented as a module in the company’s ERP system.

ERP helps bring structure to asset management by centralising data and processes. Instead of juggling multiple tools or spreadsheets, teams get a single view of all assets—whether they’re facilities, equipment, or infrastructure.

This makes it easier to track usage, plan maintenance, and avoid unexpected downtime. It also ensures compliance and audit readiness, since asset histories and documentation are stored in one place.

Think of ERP as the link between how assets are used and how they perform. It collects real-time data on things like maintenance schedules, operational efficiency, and lifecycle costs. With that information, companies can identify underperforming assets early, fine-tune usage patterns, and make better replacement or repair decisions.

Over time, this can reduce wear and tear and extend the life of valuable equipment.

ERP doesn’t just manage data—it connects the dots between departments. For example, when asset information is shared across maintenance, finance, and operations, there’s less manual back-and-forth and fewer errors.

Routine tasks like inventory checks, work orders, or procurement can be automated, freeing up teams to focus on bigger priorities. That kind of visibility and coordination helps companies respond faster and work more efficiently.