The pandemic has brought so many challenges that influenced businesses all over the world, and the manufacturing industry was among those that were impacted by the “new order”. Recently we have recently come across one interesting piece of research about digital transformation and how COVID- 19 became a catalyst for changes in the manufacturing sector.

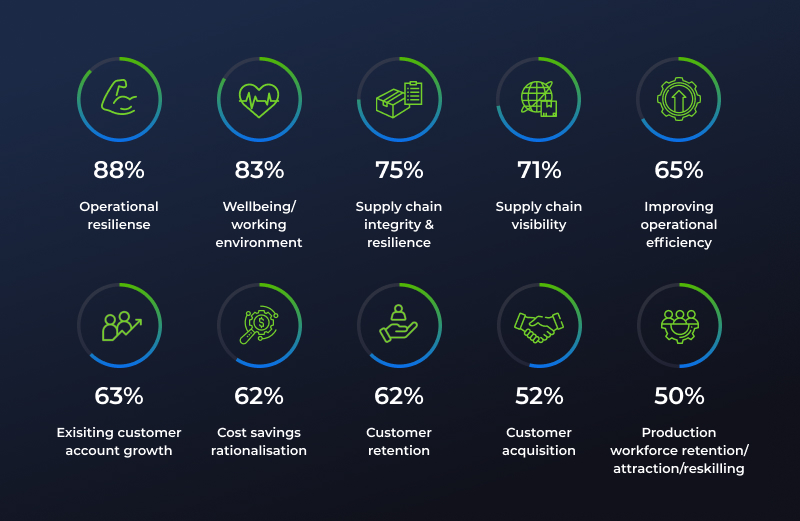

That research suggests that 67% of manufacturers have accelerated digital transformation. This is a solid number of companies that shifted their priorities and decided to focus on:

As you can see, it’s all about business growth, productivity and customer service. So the main question is – what software development do manufacturers actively invest in? Well, based on our experience, we can say that they likely most often initiate custom enterprise resource planning and MRP development.

Enterprise resource planning became a centerpiece of all manufacturing companies able to improve data analytics and further data use, automate numerous business processes, improve collaboration between the departments, and boost your manufacturing company efficiency.

In this blog post we’d like to discuss ERP for manufacturing industry and common and make-to-order manufacturers, specify some key features of this software, and emphasize the necessity of such a solution. So get yourself comfortable, as we have prepared a full guide to enterprise resource planning system development where no valuable information is missing.

When it’s time for custom manufacturing industry to implement ERP system

Custom manufacturing is a very specific and complex business. Each new order is not like the previous one, therefore you need to prepare accurate estimates, precise plan, and design specifications to provide your clients with the end product they’ve requested. On top of that you should not forget that the clients may ask to apply some changes on the go, so your business should be prepared to meet new requirements and implement them.

Let’s say you manufacture custom pieces for architectural construction and help with their renovation. The type of construction may vary, so you may need to produce pieces of different sizes, of different raw materials and even weight. Therefore you need a system to create an order, add all specifications of the required pieces, attach the drawing, assign the production to a certain team, estimate time and budget, and set a deadline. If any step is faulty, chances are you will miss the deadline or even have to redo something.

It’s all about flexibility and well-coordinated processes in custom manufacturing. And if you lack both of them, then your business is probably not doing so great. It’s really hard to coordinate all custom manufacturing processes and streamline all operations starting with estimation and ending with production and sales. That being said, it’s actually not impossible, especially if you don’t have manufacturing management software. Which is why ERP/MRP implementation can become a game changer for your business.

In case you already use some software but keep wondering when it is time to switch it for a holistic custom ERP software solution, here is a list of telltale signs than you need that ERP:

- Your employees still complete a lot of operations manually.

- There are delays in key processes.

- The communication between your departments, employees and clients is not effective.

- Your existing processes require improvements and you also want to introduce some new ones.

- The departments don’t synchronize and work like a united mechanism.

- You can’t reach your monthly productivity and sales goals.

- The data management is not efficient.

- You do not have a solution for tracking BOM (bills of materials) and spare parts lists.

- Your production planning is not precise and you keep losing money.

- You do not have a 360 degree productivity and customer profiles.

- There are no effective tools for tracking progress of each separate process and employee.

As you can see, the list of challenges you may face is pretty extensive. And among all best manufacturing software enterprise resource planning is one of the most efficient tools. ERP for manufacturing can help you eliminate all of them once and for all and streamline all your custom processes. All you need is to select the right feature set and evaluate all the benefits ERP can bring you. ERP is a costly solution, but its advantages make it worth every penny.

Benefits and drawbacks of ERP for manufacturing

ERP development and implementation is a serious commitment that requires a lot of time. Depending on ERP/MRP complexity you may spend almost half a year on developing such a solution. So is it really worth it? Is there a real value that can outweigh the development hassle? Let’s discuss that right away, laying out ERP benefits as well as its drawbacks.

ERP pros

Make-to-order manufacturing companies should embrace digitalization opportunity and invest in custom ERP software solution because they can:

- Help introduce custom order making;

- Make procurement and BOM management much easier and transparent;

- Help delegate processes to advanced technologies;

- Provide tools for effective communication between departments, suppliers and customers;

- Assist in facilitating the pricing and comparing actual project cost vs estimated cost and avoid financial losses;

- Provide solid database where your employees can find suppliers, similar projects, templates, or list of resources effortlessly;

- Make every process visible and easy to manage;

- Perform accurate forecasting on production;

- Predict possible bottlenecks and perform effective risk management;

- Store data in one centralized place and use that data to get holistic reports and an overview of all core business processes;

- Provide better control over your business and let you focus on specific needs of your clients;

- Help you effectively manage company workload among your workforce and ensure appropriate delivery conditions.

Custom manufacturing ERP software has way more advantages than we mentioned. This is a serious business solution that will be adapted to all your specific and core business processes, so you will not need to use several separate solutions anymore.

Manufacturing ERP system is a multifunctional software that can have dozens of modules and integrations. Everything depends on your needs and customization level you’d prefer. Custom manufacturing software is great in terms of adaptation to all your business requirements.

ERP cons

Speaking about the disadvantages of ERP for custom manufacturing industry, we would like to point out that, frankly, there aren’t so many of them. And yet they are present and you should be aware of them. Here are the main cons you should pay attention to:

- Custom manufacturing ERP software is costly, so you should be prepared to pay around $50,000 per month of development if your goal is to build a feature-rich solution. Also, the maintenance of an ERP software may entail some additional costs as well.

- It takes time to deliver manufacturing ERP, integrate it with your other systems and train your employees to use it. On average you may spend 6 months on this venture.

- The transfer of data is very complex and requires a strategy so that all information can be successfully moved to a new system.

- You need a truly experienced development and delivery team because otherwise you can exceed the budget that you initially set out or even deal with implementation failures.

Why ready-made enterprise resource planning is not enough for custom manufacturers

At this point you may be questioning the need to have none other than a custom ERP and MRP solution for your manufacturing company. After all, there are so many great ready-made ERP software on the market. So why invest your time and money into something so expensive? Well, simply because ready-made solutions are not a perfect fit for every company, and you as a custom manufacturer are bound to already know this.

To begin with, if you go with the ready-made ERP you will depend on its vendor for servicing. And should any changes occur, you will have to adapt to them and look for new ways to complete certain business processes.

The next disadvantage of ready-made ERPs is that their scalability and security are questionable. So if something happens to the server where all the data is hosted, you may face irreversible consequences.

For custom manufacturers even a couple of hours of delay means a lot, and imagine what can happen if all processes will stop for a day because there is an issue with your off-the-shelf ERP systems. And last but not least, such ERPs do not offer enough customization. Integrations can be a bit limited too. So chances are that you may need to incorporate a certain option in your manufacturing ERP system but will not be able to do this due to the limitations.

Although all ready-made manufacturing ERPs can be called affordable even for big businesses, they will not be able to turn your manufacturing companies to a whole new level. Yes, you will definitely improve your productivity with those ERPs, but you will not overcome all your specific challenges.

Some manufacturers still use well-known ERP software such as Oracle ERP, MS Dynamics, SAP Business One and Epicor. And yet many of them claim that they lack certain options. Here is a table that summarizes what those ERP software has to offer:

| Features | MS Dynamics | SAP Business One | Epicor |

| Document management | + | – | + |

| Project management | – | – | + |

| Accounting | + | + | + |

| Reporting & analytics | + | + | + |

| CRM | + | – | + |

| Quality management | – | + | – |

| Mobile ERP | + | – | + |

| Workforce management | + | + | – |

| Role-based permissions | + | + | + |

As you can see, even commonly used reputable ERP software might not be able to cover all your business needs, especially taking into account that you are involved in custom manufacturing and some specific options are a must-have for you.

Therefore it is better to invest in custom manufacturing management software and get an ERP for make to order companies that will grow with your business, expand its functionality according to your emerging needs and boast a high level of security and possibility to recover all information in case an accident occurs.

Top 7 industry-specific ERP features for custom manufacturers

We already developed complex ERP and MRP solutions for custom manufacturers before (for example, one of them was involved in production of custom construction pieces, and another one produced spare parts for police, the fire department, paramedics and other emergency response vehicles). Not only have we gained a large amount of experience on those projects, but also discovered and got a better idea of what industry-specific features every manufacturing ERP software should have. Let’s take a look at them all together:

Power up your business with manufacturing ERP software developed by us

In case you’ve made a decision to develop an ERP solution for your custom manufacturing business, you need a reliable technical partner like our team. We have developed ERP systems for different businesses and several of them were involved in custom manufacturing. Therefore with our team you can be sure that we understand all your business challenges and are able to find a technical way to resolve them.

When it comes to custom ERPs for manufacturing companies we not only have a vast experience but also can guarantee you the following:

- full immersion into the actualities of your business industry;

- accurate technical documentation;

- diversification of development risks;

- selection of the most suitable technicians;

- clear code and high-quality testing;

- regular progress and financial reports;

- impeccable project management;

- preservation of set deadlines and budget.

We are ready to provide you with a full team of specialists who can develop and implement a feature-rich ERP for manufacturing. The list of the specialists we provide includes:

- Business Analysts;

- Software Architects;

- DevOps;

- Designers;

- Front-end developers;

- Back-end coders;

- QA engineers;

- Scrum Masters.

The team composition can be changed if your project requires only certain specialists to be added to your in-house team. Our approach is quite flexible, so you don’t have to worry about any technical-related aspects as we will take care of them. You just get a great custom manufacturing software with minimum input from your side.

Examples of ERP systems we developed

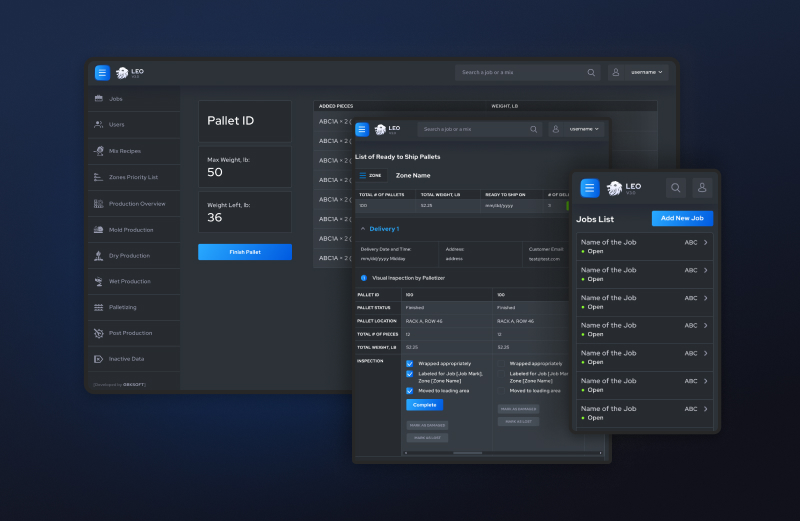

We know that examples speak louder than words, therefore we’d like to share with you information about several projects we are very proud of. The first solid ERP platform we’d like to showcase was developed for the company called Nelson Precast that engages in manufacturing of custom construction pieces and installations.

Before that ERP system was integrated, the company experienced a lot of productivity challenges. It was hard to track manufacturing operations, manage orders and preserve production deadlines.

Before that ERP system was integrated, the company experienced a lot of productivity challenges. It was hard to track manufacturing processes, manage orders and preserve production deadlines.

An ERP developed by us helped to eliminate those and many other, more minor issues. The ERP is called LEO (you can check it out in our portfolio), and it offers a wide variety of features any custom manufacturer would appreciate. Here are some of them:

- Barcode scanner to track progress of production of certain pieces;

- PDF uploader and editor to make order making more custom;

- Project planning module to schedule everything properly;

- Advanced search to find previously and newly produces pieces in a database;

- Job management module for better productivity;

- Checklists to ensure easy quality management of produced pieces;

- Delivery tracking module;

- Holistic production overview.

LEO’s design is very intuitive and user-friendly. All employees have gotten used to the new ERP really quickly and were able to find necessary options on the go. Here is how the LEO interface looks like:

One more great ERP system was created by us for a company that is involved in the production of spare parts for specific service transport. The main challenge for the company was that its employees had to manually enter orders and specify all information over and over again. Also it was hard to find spare parts in storage using part numbers. So to eliminate these issues the company decided to develop an ERP system.

Our team explored all challenges and processes of this company, wrote detailed specifications, worked on functional and non-functional requirements and developed an ERP system full of useful features such as:

- inventory management module;

- mobile optimization;

- customer management module;

- vehicle profiles that include all parts produced by company;

- module for services management (listings, forms, requests).

As you can see, ERP systems for different manufacturing companies can include different sets of options. Everything depends on your challenges and business goals. Our team can help you perform a digital transformation of your manufacturing company and reach new, more ambitious revenue and productivity results.

ERP development services we offer

With our team you can not only develop a custom manufacturing ERP software from scratch, but also modernize your existing solution and spice it up with the latest technologies and most useful options. When it comes to ERP development services, we offer:

- SaaS ERP development;

- Mobile ERP development;

- Custom ERP development and implementation;

- ERP modernization and legacy code review;

- Implementation of advanced technologies such as IoT, AI and machine learning;

- ERP integration of all necessary services and connection to your other systems;

- ERP maintenance.

We are also experienced in team augmentation. So if you already have a core in-house team but lack extra hands or specialists with certain sets of skills and experiences, we are here to help you. You can scale up with us easily and speed up the manufacturing ERP development and implementation.

Speaking about cooperation models, we offer not only team extension, but also dedicated team services. So we can work equally well together with your technicians or take full responsibility for your project and all development processes. Whatever option you choose, we guarantee you the best end result.

Budget you should have for custom development

Custom manufacturing ERP is a costly solution, and an average monthly check for its development may be up to $50,000. Depending on the ERP complexity, selected tech stack, feature set and team composition, the development may take anywhere between 4-6 months.

We would recommend you to get in touch with our team to get a quotation for your manufacturing ERP or request a rough estimation. This will help you to get a full picture and understand how much money your particular custom manufacturing software requires.

We are ready to consult you, perform the Discovery stage and provide you with the estimation document, project specifications and requirements. All this information will help you understand how much time the manufacturing ERP development will take and how much money you’re going to pay per month for each specialist’s work.

FAQ

To summarize

In times when customers become more demanding than ever and competition gets tougher, all manufacturers need reliable business productivity tools able to optimize processes. An ERP system is one of those tools. Although custom manufacturing ERP development is costly, it can grant you ample business advantages.

Custom manufacturers can definitely make good use of ERP systems full of industry-specific features and integrated with other solutions. Manufacturing ERP software for make-to-order companies helps with business automation, more accurate estimation of labor and resources, visibility of all processes, workforce management and many more.

But what’s even more important is that with manufacturing ERP you can become a highly profitable and client-oriented company. So if you still don’t have a great ERP system, it is time to acquire it.