Table of Contents

While the project management practices have become so agile and advanced in their approaches that most of the industries have successfully applied those to save their costs and increase sales, the construction industry is still lacking the proper experience in it. Sometimes it seems that construction companies have simply accepted and let go of the fact that the projects they start will miss the deadlines and will probably go over the budget.

Problems and pains of the construction industry

And if you check the pain points of the construction company owners, you’ll see that most of them are connected with one of the next items:

- The overextended process of estimations and quote issue, which lowers the probability of getting a deal. So we are talking here about the need for project bidding process facilitation.

- Execution discrepancy, which leads to additional expenses. Per most of the contracts the flaws that were admitted by a construction company during the manufacturing are due for a correction at the cost of a construction company.

- Staff shortage and human errors are other factors that lead to projects going over budget and the need to control the unskilled staff by adding more checklists to fill in. As a result the bureaucracy grows and the project delivery gets delayed.

- Communications and notifications require the unified information flow especially for the construction companies working around the globe.

- Construction waste is the growing problem, which can also lead to the fines and additional fees depending on the country of operation.

- Inventory track. I bet everyone who reads this article and ever worked in construction experienced that ready materials or manufactured pieces just disappear and no one knows where to look them for. And of course, this leads to excessive costs

- Delivery and sign off stages are usually very uncertain and sometimes the delivery of the ready-made pieces for smaller construction companies that manufacture only certain pieces of the entities can last a couple of months. Moreover, something that needs to be delivered to the construction site, in the end, is delivered at the beginning, which leads to loss, breakage, or excessive storage expenses.

However, you can notice that most of these problems are also proper for other industries, which means these problems have been successfully resolved by introducing software technology into the management of the day-to-day activity of the companies. In this article we will give an understanding of how the development of your software management system can eliminate or significantly decrease the impact of mentioned problems based on a few examples of construction companies that have already implemented this.

How software can help to speed up the process of estimating and bidding?

When inviting the companies for bidding the end clients or just contractors send out the requests for offers to several companies and usually they’re looking for a price for the project or a separate piece like e.g. cast stone. And since the constructions contracts are not easy to receive and there are not so many of such it is extremely important:

- To bid in time

- To keep your bid as low as possible

- To know other bidders.

How a web portal cuts the average deal closing time almost twice

A client of ours, a construction company that specialized on the development of custom made architectural precast concrete had the next flow of estimation:

- Architectural drawings preparation by an estimator

- Determination of the approx amount of work on the project

- Set of the price by the company president

- Sending of the bid

So what we did is just automated the process.

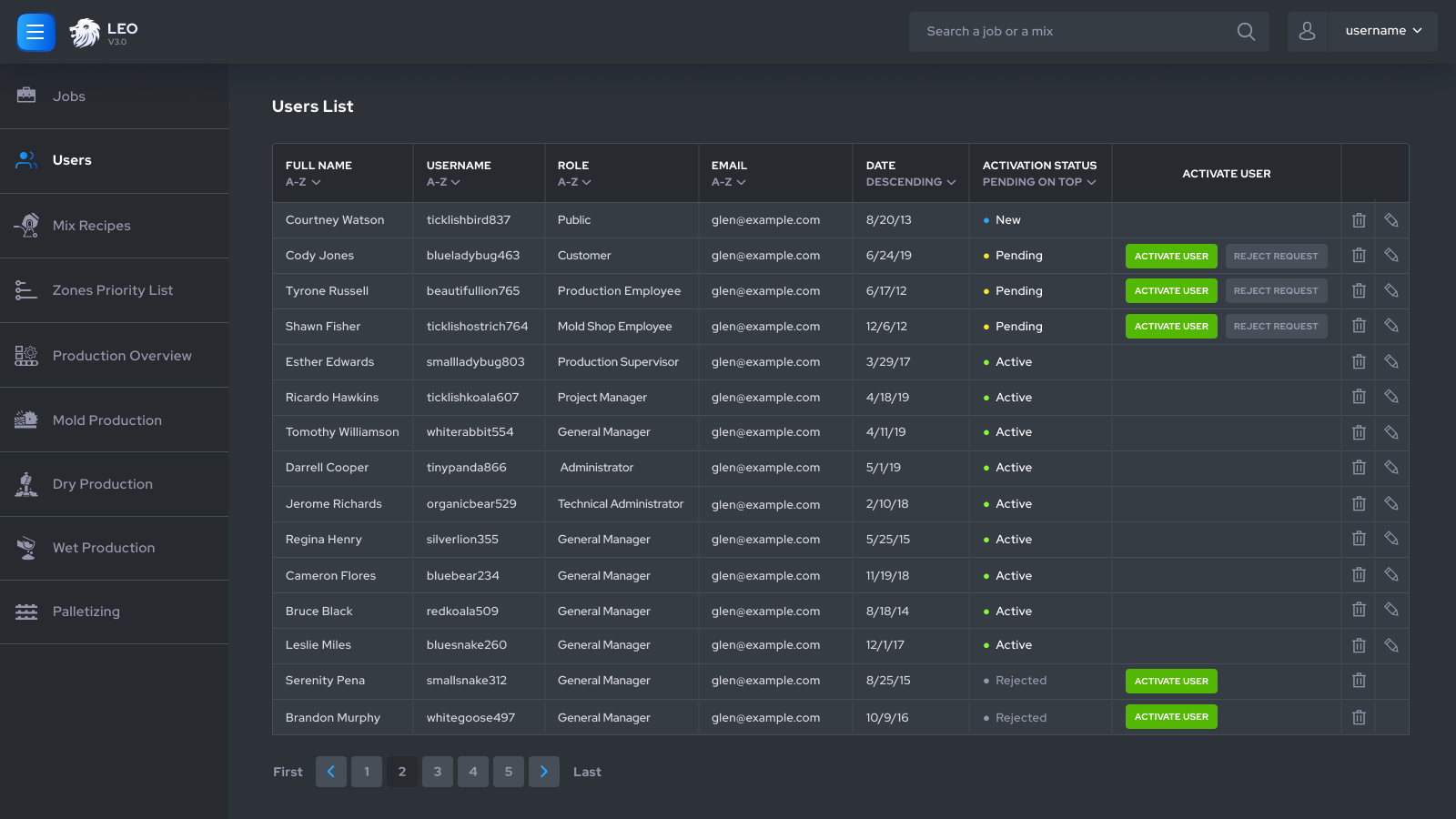

- When the new invitation to bid (this particular company had the invitations sent to them by email) is received, the script defines such invitation emails and automatically creates a new project deal in the web portal available to the sales team of the customer.

- Once you log in to this secure portal, the deal is assigned to the responsible architect to do the drawings.

- Once the architect starts the work, they put the deal status into “ in progress”. On the finish the ready drawings are attached to the deal.

This gives the general overview of how many deals are in progress and the expected due date for those.

- The next stage would be for the software to scan the documents and break them down into the pieces that require production, identifying their cost of production. When the software recognizes the pieces defined in the drawing, it can now automatically generate the total quote based on the prices.

And there’s more to it, a sales manager can compare the quote to the other bids from their past projects to make a better decision on the offer price.

As a result, this construction company was able to gain:

- The unified list of all bids won, in progress and lost

- Clear vision at what stage the bid is at any point of time

- People responsible for it

- The company president has saved huge time on providing the costs. Now he only needs to confirm the bid in the web portal.

There’s much more to what can be done here and of course the flow automation is very dependent on the specific needs and problems your bidding process experiences.

How to automate the full manufacturing lifecycle with web portal or mobile application?

The construction project must be perfectly executed with the best expectations of your customer. It’s important that the construction process is well controlled at each stage and all pieces ordered from subcontractors are delivered in time and of sufficient quality and in the defined quantity.

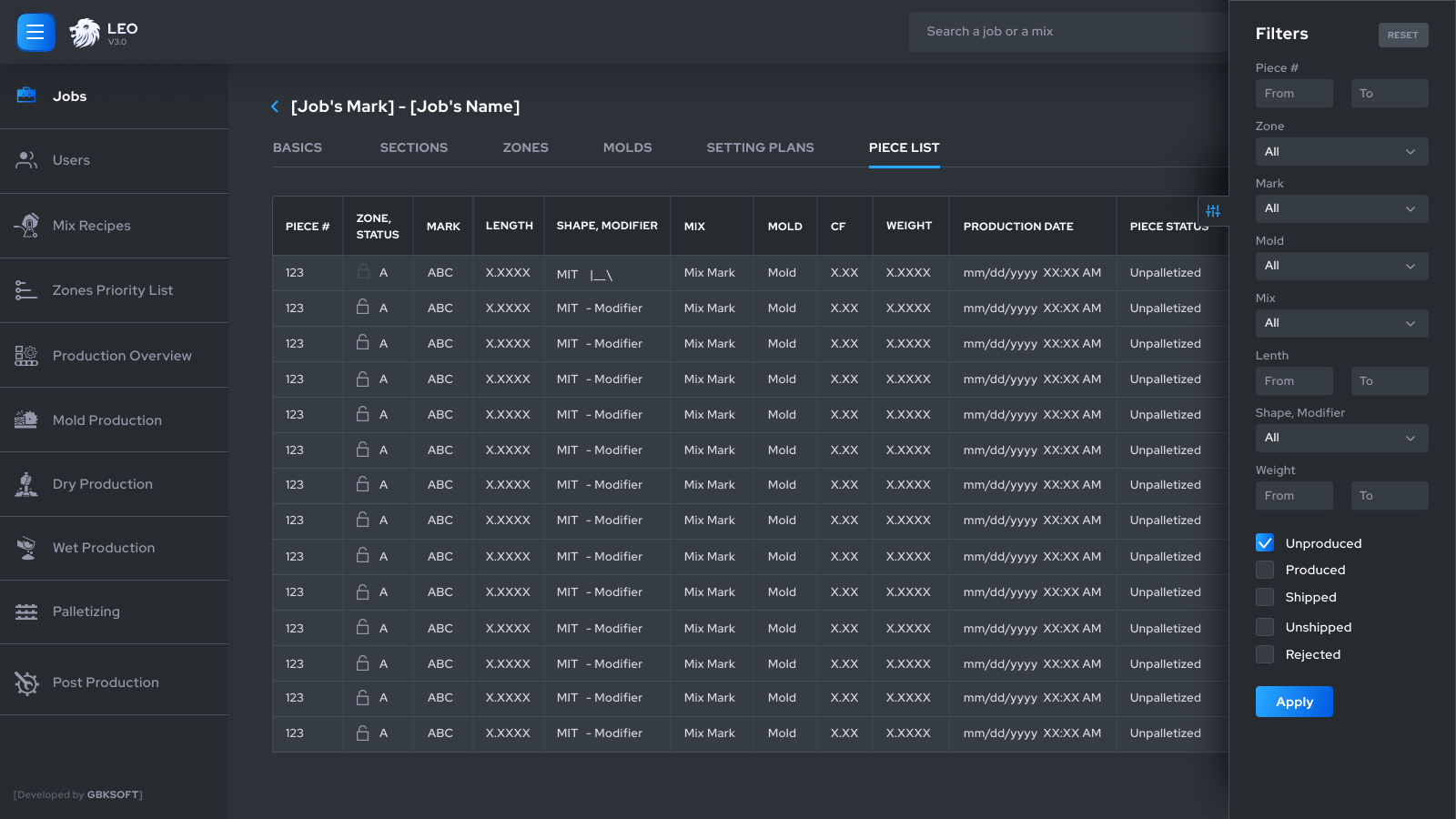

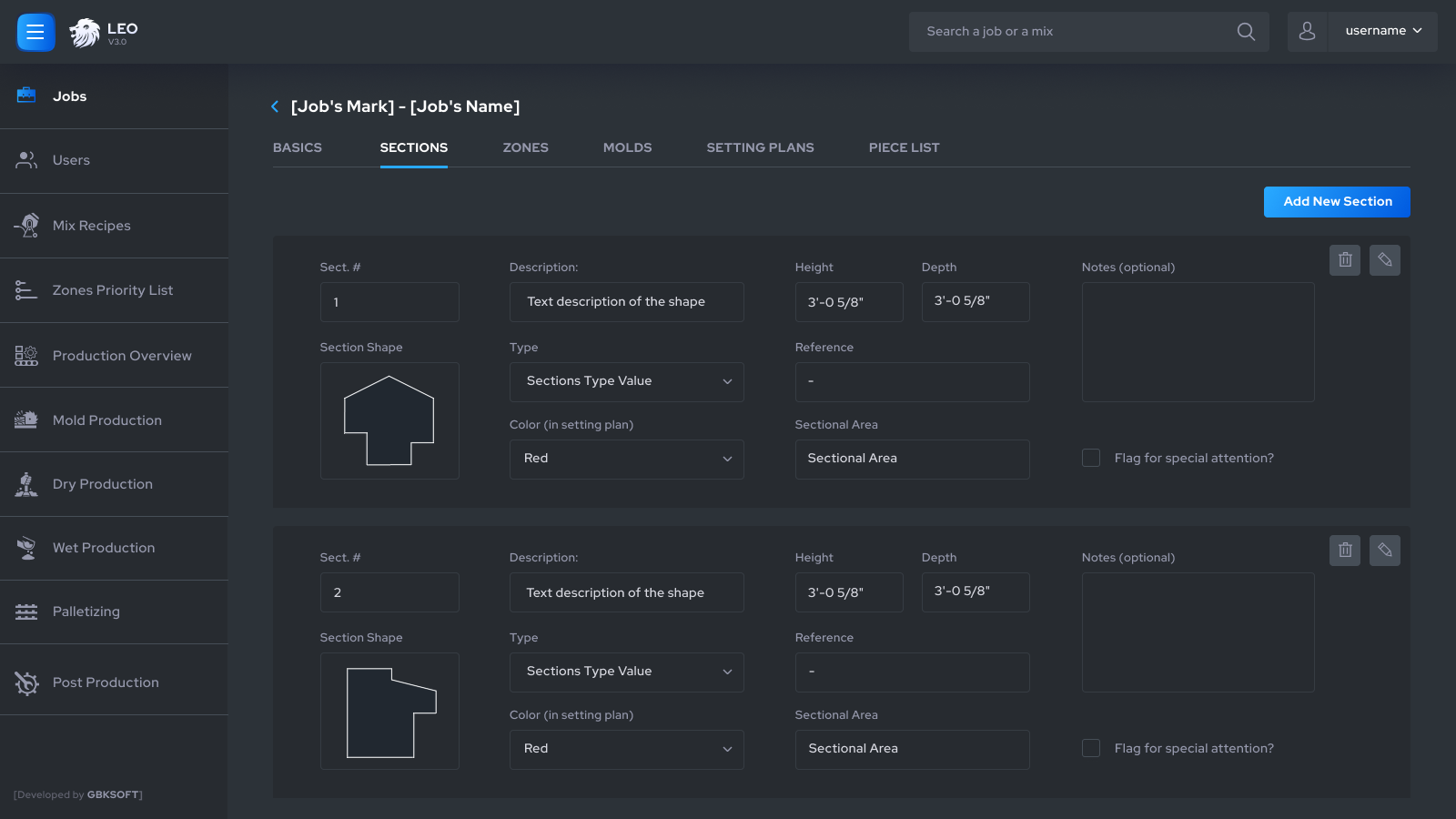

So let’s get back to a construction company we referenced in the previous section. Once the project is awarded and the submittals are accepted, the project manager is assigned and from this moment the production process begins. It’s important to mention that this particular company produces the decorative pieces for the building exteriors, so their production process is pretty much the manufacturing of those decorative pieces.

The project created in the system has a list of pieces that are inherited from the previous stage. The project manager breaks the list down into the priority zones that will define which pieces go into production first and which are of lower priority. Moreover, the system measures the actual labor and materials against the expectation by project, department, and employee, making sure the project stays within the budget.

Another innovation here was the unification and track of all inventory of the company. Essentially this looks like just the list of everything that can be used for production. And once this was done, we found that some of the molds that have already been produced can be reused to produce the pieces bringing the costs of their production down. But before such molds were either wasted or lost. So the system was optimized to automatically suggest available molds that are available for reuse.

Besides, the full lifecycle of stone was automated by adding the barcode labels to the pieces. This way any piece could be tracked by just scanning its barcode that provides its status, location, responsible people, zone priority, and other required details.

Due to effective quality control and sign off, the pieces that do not meet requirements were identified at early stages also leading to essential savings.

So just the automation of workflow allowed to save money on:

- Execution Discrepancy

- Inventory track

How to reduce the employees workload by using a mobile application?

The main problem with the workload as well as consequences this might lead to are:

- Human errors

- Repetitive data entry

- Low productivity

- Complicated integration process of newbies.

Let’s review how this was resolved on the example of another construction company. This particular one had a staff of more than 100 employees. All problems listed above were a usual thing and supervisors were simply giving up.

Human errors were certainly reduced by automating those processes that were critical in terms of deadlines or quality of the construction. Here drones mainly helped with the max automation of visual inspections, deliveries, scanning of locations, etc. This allowed to lower the human errors almost twice especially in connection with the data entry.

All production statuses and reporting were substituted with the automated check-in, issue of to-do for the day, the report by the employee at the end of the day through actual photos and videos uploaded to the cloud.

The way it works is that each employee has a mobile application. When an employee starts the day, they check-in. At this point the timing track for the working day starts. Employees can pause and resume the working day for lunch.

Once the day is started, they receive the task list for the day in the priority order. If the task requires the supervisor’s control, then it goes to the application of the supervisor before it can be completed.

All data entry happens through scanning of barcodes instead of searching and inputting data. This allowed us to avoid human error and stop losing construction inventory elements.

Newbies on start receive an onboarding program, where they have the contact details of everyone they might need, frequently asked questions, supervisor’s contact details – all in one mobile application. This allowed them to hire less skilled people, become more competitive, and cut the costs of hire.

How can the construction industry benefit from the web and mobile application that optimizes communication with partners and customers?

Whether you are a small company or a big conglomerate, communication is always an important part of keeping the work efficient. Just the uncertainty, lack of communication of new regulations in the industry, misunderstanding cause billions of dollars to the industry yearly.

Optimization of communication with software can save you time by automating the flow. Instead of having the employee connect with another department, the system does everything for them. For example, the production of a medium size construction company required the next flow of communication:

- The production department has the production process completed

- Supervisor calls the delivery department

- Delivery department checks the paper schedule of employees and assigns the employee

- Employee collects the produced work and brings it to storage

- Then reports back to the supervisor

- Supervisor reports to the production department confirming the acceptance.

The way software helped the process is: once the production is complete, the delivery department receives automatic notification of this. The supervisor receives suggestions on free employees for assignments and only confirms the executor in their portal. Employee executes the work, assigns location to the produced piece, which triggers the confirmation report to the project manager, supervisor, and other people on the watch list.

All representatives of C-level and higher management have the option to send out the notification to all their employees or a specific department or person.

The software also reduced the number of communication itself, cause now instead of verifying the status of the construction stage from the responsible people, customers, supervisors, managers were kept up-to-date by the system by triggering notifications to emails and as push notifications to their mobile phones.

How web software can help with construction waste?

Construction waste management is usually based on several levels, which covers the project level, company, industry and the governmental one. With the help of web application one of the construction companies that requested the software development introduced the next waste management system at the level of project:

- During the design architect and engineers define the levels of the expected debris.

- Software uses the self-learning AI that based on the defined items gives recommendations on the potential decrease of waste and how the design can be enhsanced to meet the lowest debris level.

- Once the design is finished and the correspondent waste level is set, it is carefully monitored later on, where at each stage, its level is reported to the system. The alert system signals on the approach of the critical level.

- If at any stage the level of waste is exceeded, the responsible people for that stage have to report why this happened.

- The workers responsible for meeting the goal of the waste level at their stage were getting additional bonuses.

Now this company looks to go even further by adding other practices such as sorting, tipping, picking of construction waste too.

Introduction of such flow allowed to decrease the waste by 30%, which serves the cause of nature and the cause of essential cut of expenses.

Automated Delivery and Sign Off control

The delivery stage is the last but not the least stage and requires automation and is aimed to make sure that all works are completed and everything is delivered. The way software can benefit here is by showing you what is left to be done, what documents need to be signed off. The countries the legal system of which supports the e-signatures can also benefit from the digital documentation and signing, which can simplify and speed up the full process, not to mention save the human hours.

The construction companies that have to also deal with the delivery of their materials to the working sites can benefit by automating the system of the trucks’ expedition and logistics. The software can allow the building of the routes, optimization of such routes into most reasonable ones, automate the printing of the delivery slips for the drivers, etc.

Conclusion

There are so many more things that tech can help in manufacturing, production and construction that you can even write a book about it. But to sum up, by using modern technologies such as iOT, Drones, Mobile and Web Development you can:

- Automate the quote building process

- Automate the productiong flow management

- Automate reporting

- Introduce proper notifications and communications systems

- Optimize human resources

- Keep people safe from hazardous waste and works

- Keep your customers and end clients informed by allowing them to view certain parts of your system.

If you are still reading, the question you probably have popping up in your mind is: “How much does it cost to build the project management software for a construction company?” Currently, there’s no ready-made unified solution for the construction industry. There are a couple of products on the web with several features listed in this article, however, most of them need adaptation and are more generic rather than tailored specifically for the need of a certain company. The reason for such a lack of systematic choice is the difference in processes each company has. So here the choice is to either adapt to what is already there or develop a custom system. The development of a project management software for a construction company from scratch would cost around $100,00 -$150,000 depending on the number of features. Based on the experience of our company this budget is sufficient to cover all major flows in the medium-sized company. If your company is smaller or bigger, the budget can be more or less, the dependency here is the number of features that need to be developed to cover all flows in the company.

To finish this article, I would like to mention that the development of a custom software also helps to organize processes in the company. Sometimes even big businesses that are supposed to have everything organized are drawn into bureaucracy and lack of management. And when all company stakeholders meet together to form the requirements and agree on the workflow that needs to be automated in the system, it leads to simplification and organization of all company processes. This is a nice award you get from technology. Since technology likes order, it brings the order into the business too.