Automate quality assurance processes

Defect Recognition

At Altamira, we understand that delivering a flawless product is a top priority for business success. We offer cutting-edge technology that scans your product in real time to identify and address defects before they reach your clients.

15+

Years expertise

140+

Satisfied clients

120+

Team members

Defect recognition use cases

Production line monitoring

Implement real-time defect detection on production lines, enabling immediate intervention and corrective action. Reduce wastage, improve yield rates, and enhance overall operational efficiency.

Predictive maintenance

By using defect data and analytics, manufacturers identify patterns and predict potential equipment failures or wear, enabling proactive maintenance and minimising unplanned downtime.

Supply chain quality control

Ensure consistent quality standards across the entire supply chain by implementing our defect recognition solution at various checkpoints, from raw material inspection to final product assembly.

Root cause analysis

Gain valuable insights into the nature and root causes of defects through detailed defect analysis, enabling targeted process improvements and preventing recurring issues.

Regulatory compliance

Meet strict industry regulations and quality standards by demonstrating consistent quality control measures backed by our defect detection capabilities.

Altamira is trusted by

Strive for excellence with Altamira

Altamira has been awarded numerous times for its performance and achievements. Join our community of successful customers, whom we helped to build and grow their businesses through defect recognition solutions.

The main challenges we solve

Overcome all these challenges with our AI software solution.

Cost reduction

Minimise production costs associated with scrapped or reworked products by identifying defects promptly and accurately.

Operational performance

Streamline quality inspection workflows, allowing for faster inspection cycles and reduced downtime.

Consistency in product standards

Maintain consistent product standards across batches by implementing reliable defect recognition systems that provide consistent results.

Customer satisfaction

Improve customer satisfaction by delivering products free from defects, enhancing brand reputation, and reducing returns or complaints.

Data-driven decision making

Collect and analyse defect data over time, identify trends, and implement proactive improvements to enable data-driven decision-making.

Labour intensity reduction

Reduce reliance on manual inspection processes, freeing up skilled labour for more strategic tasks and reducing labour costs.

Take the next step

Let’s treat the core problems, not symptoms.

Receive a personalised project estimate and take the first step towards bringing your idea to life.

Explore our case studies and find out how we have helped some of our clients from around the world.

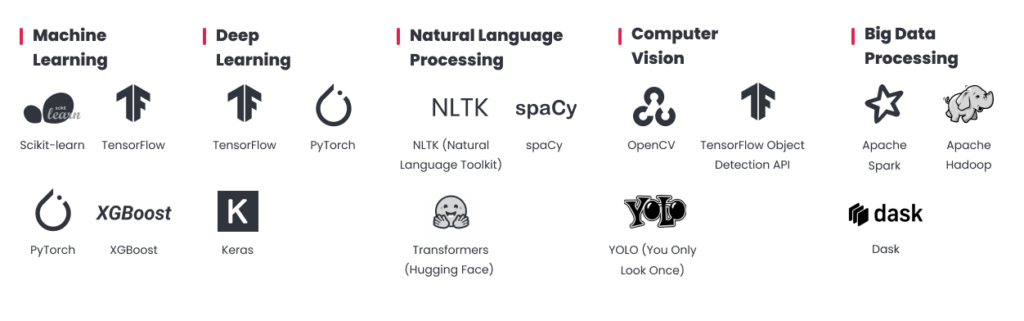

Our tech stack

Our diverse and dynamic tech stack is carefully curated to ensure smooth integration, scalability, and performance, tailored to meet the unique needs of your business.

Explore our full range of services

Identify and assess vehicle damage and activate insurance policies on the spot without any need for expert assessment.

Transform your visual data into actionable insights, enabling accurate image identification and categorisation for various industries and use cases.

Eliminate manual data entry, categorise documents, process images, or transcribe videos, converting text into digital format.

Automate processes, gain insights into customer behaviour, and product performance with real-time object detection and classification.

Streamline store operation, improve inventory, and level up customer experience with accurate item identification.

Case studies

Custom mobile app for dog owners

Modern technology can help owners care for their dogs and keep them safe. GPS tracks and saves dogs’ history for their whole life, easily transfers it to new owners and ensures the security and detectability of the animal.

Training app powered by IoT

A golf training app that helps players improve their unique golf style. An opportunity for a deep configuration of the swing goal, great visual support, advanced algorithms, and effective feedback makes this project a revolution for golf!

AI-powered web and mobile app solution development

In response to the need for accessible neuropsychological assessments, Altamira introduced a transformative solution that reimagines the traditional approach to diagnosing and monitoring cognitive, mood, and personality disorders in children.

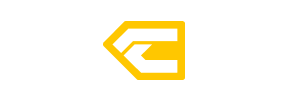

All-in-one solution app for local businesses

A native iOS and Android app that connects neighbours and helps local businesses to grow within local communities. Bestyn includes posts sharing, private chats, stories and built-in editor for their creation, and tools for promoting local businesses.

Mobile payment and virtual terminal app

The SkipCash mobile payment app is operated in Qatar, where common PoS terminals are not widespread. SkipCash tries to solve this problem with a mobile payment app that replaces the payment terminal on the seller's side and replaces the payment card on the client's side.

Slovak National Theater web development

We took over the maintenance, continuous improvement, and further development of the website for the most famous and largest Slovak cultural institution – Slovak National Theater.

People also asked

By analysing images or sensor data, AI systems can detect imperfections that might be missed by the human eye. As a result, the inspection accuracy and speed are significantly improved, allowing for real-time quality control and reducing the need for manual inspections. Contact us to learn more.

AI plays a key role in quality assurance and defect detection by automating the inspection process, ensuring consistency, and reducing human error. It also helps in maintaining high-quality standards, and optimising production efficiency. With AI, businesses can implement predictive maintenance, monitor production lines in real-time, and quickly identify any anomalies or defects.

AI can be used to detect a wide range of issues, including:

- Surface defects such as scratches, dents, and cracks.

- Structural flaws like misalignments or deformations.

- Anomalies in data patterns indicating potential problems.

- Quality deviations in manufacturing processes.

- Faults in mechanical components.

Contact us to get an expert consultancy.

AI anomaly detection refers to the use of artificial intelligence to identify unusual patterns or behaviours in data that deviate from the norm. This technique helps to spot potential defects, security threats, or system failures. AI models learn from historical data to establish a baseline of normal operations, and any significant deviation from this baseline is flagged as an anomaly.

All our services

Services provided by Altamira

Software Care

Software Development

Artificial Intelligence

Outstaffing

Looking forward to your message!

- We will send you a confirmation email once your message is received

- Our experts will get back to you within 24h for a free consultation

- All information you provide will be kept confidential and protected under NDA

- We will provide an initial project estimate during your consultation